Shandong Iraeta Grinding Media Steel ball For Mining ,Cement plant

Product Description

1 ) Product feature

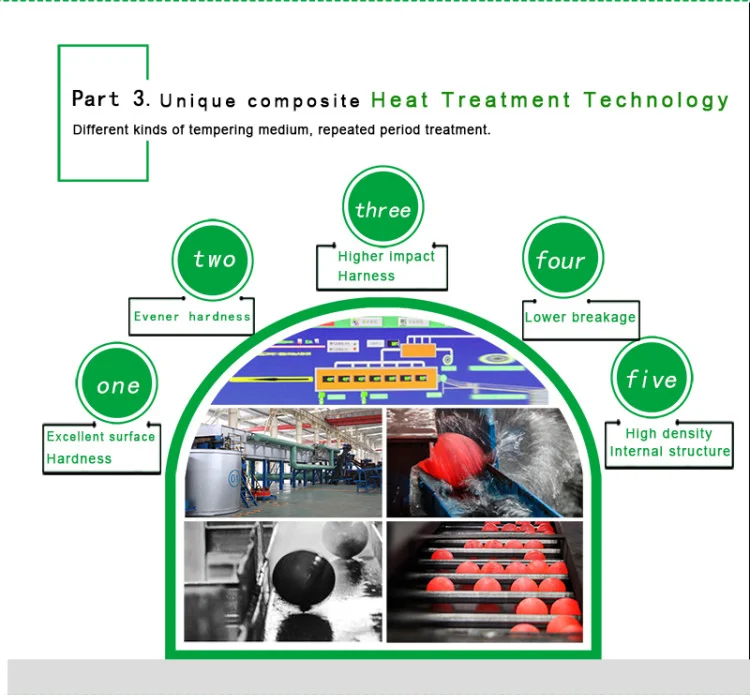

1 > High Hardness: Surface hardness: HRC57-67 HRC, volume hardness HRC56-64.

2 > High Impact Toughness: The impact toughness of our grinding balls is more than 12 J / cm2.

3 > Low Broken Rate: the actual broken rate is not higher than 1%.

4 > Good wear-resistant and lower wear rate.

Company Information

Shandong Iraeta is a Sino-Spanish joint venture and its shareholders include Gestamp group which is the biggest steel deep processing enterprise of Spain. Shandong Iraeta has been one of the leading forging enterprises of China since it started business in 1975, Until now, it owns more than 20 international and industrial certifications and has assisted the draft and approval of two national industrial standards as well as one Torch Program project.

With over 20 of the global top 500 enterprises purchasing various kinds of forgings from us for different uses, we have customers in the fields of mining, shipbuilding, Petrochemical industry, wind power mechanical manufacturing, ect.

With over 20 of the global top 500 enterprises purchasing various kinds of forgings from us for different uses, we have customers in the fields of mining, shipbuilding, Petrochemical industry, wind power mechanical manufacturing, ect.

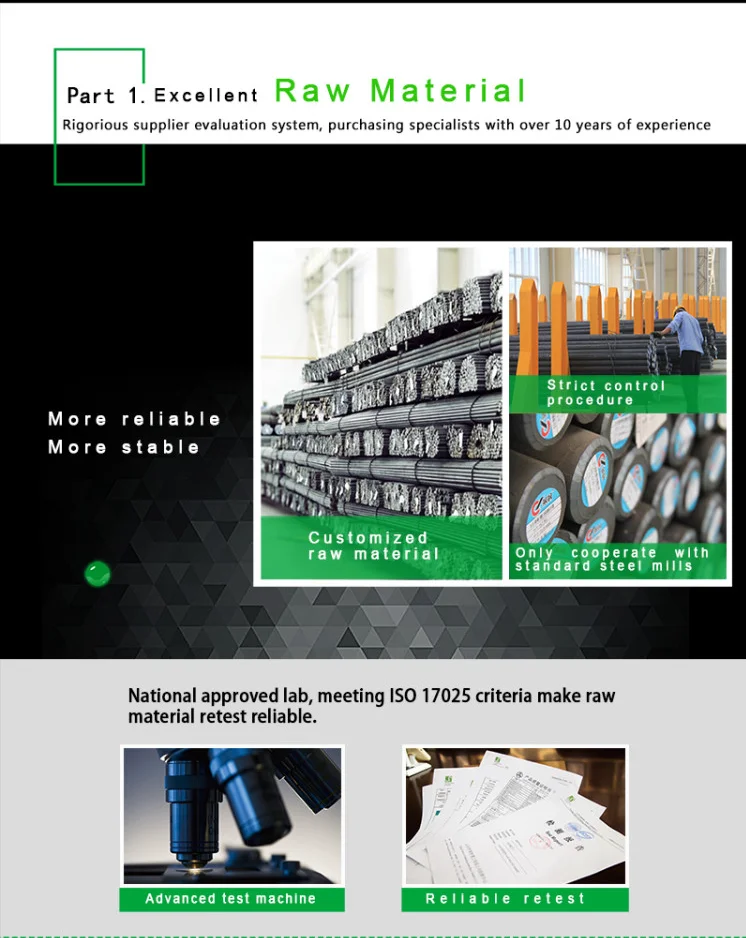

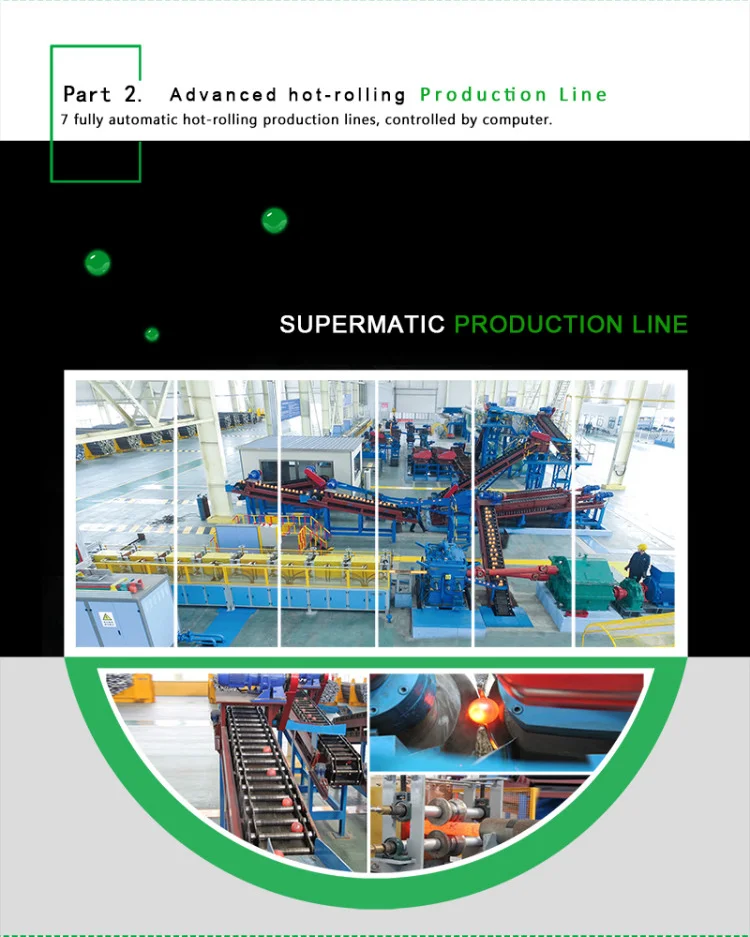

WHY CHOOSE US?

Our Services

1) 20 years experience in global services

Shandong Iraeta have service overseas experience for more than 20 years, we fully understand

the complexity and diversity of customer demand from different areas, whether in business,

technology, quality and logistics.We in more countries and regions in the world to se 44t up his

own offices or technical service center, in the center of the fastest services customers, for

customersto resolve the problem.

If you have any questions , please contact to me.